Pipe Marking Seaward Safety

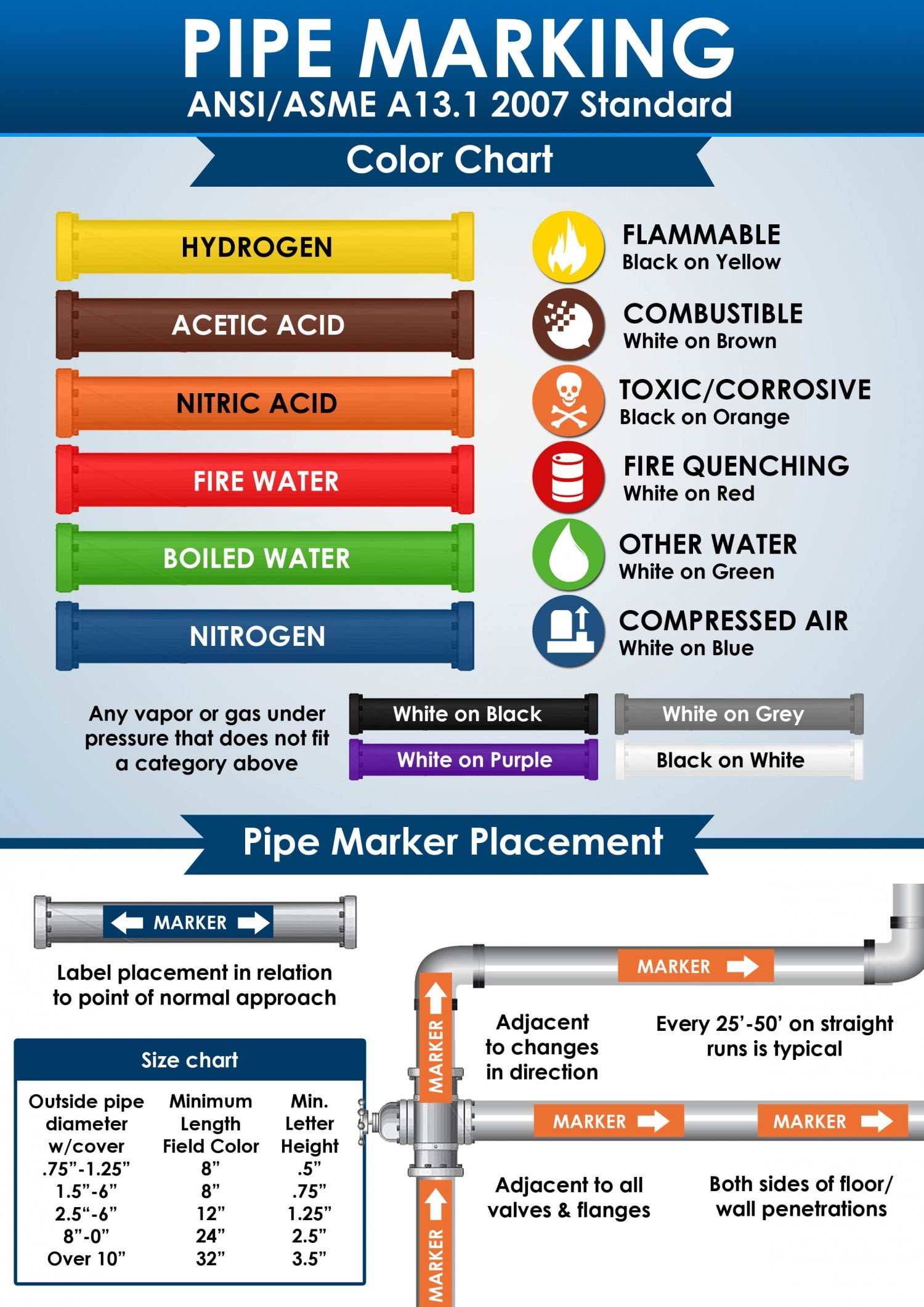

ANSI / ASME A13.1 is the most common pipe identification standard used in the United States. The standard specifies the primary and secondary means of identifying pipe content, as well as, the size, color and placement of the identification device. 1. Primary Identification

Pipe Marking bengeck48 Medium

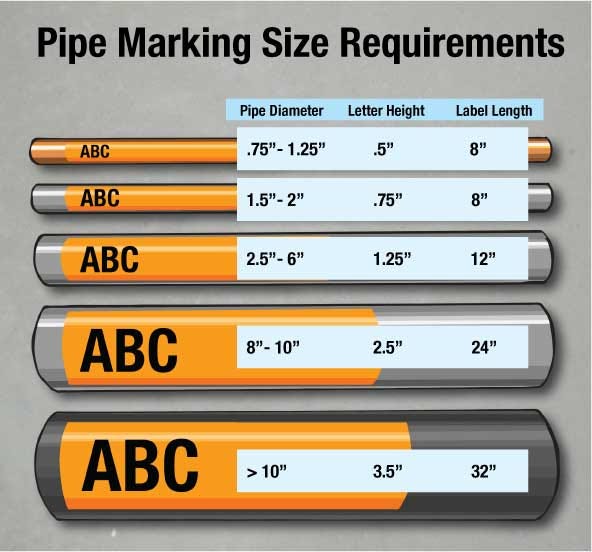

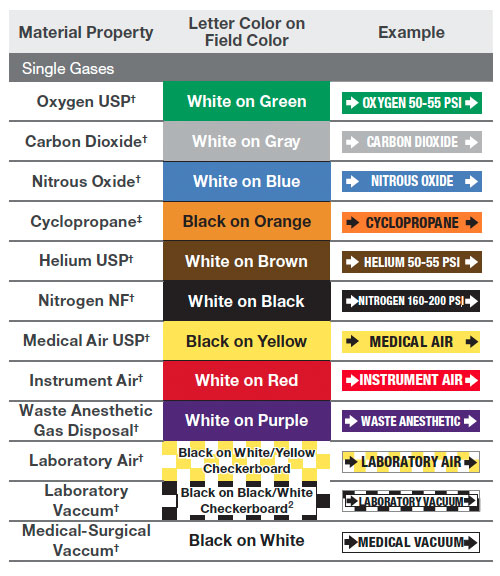

Pipe Color Code Chart - ANSI/ASME A13.1 Pipe Marker Visibility and Size Requirements The ANSI standard A13.1 on pipe marker visibility and size requirements was updated in 2020, resulting in slight changes from the previous (2015) requirements.

Pipe Color Code Standard and Piping Color Codes Chart by steelpipesfactory Issuu

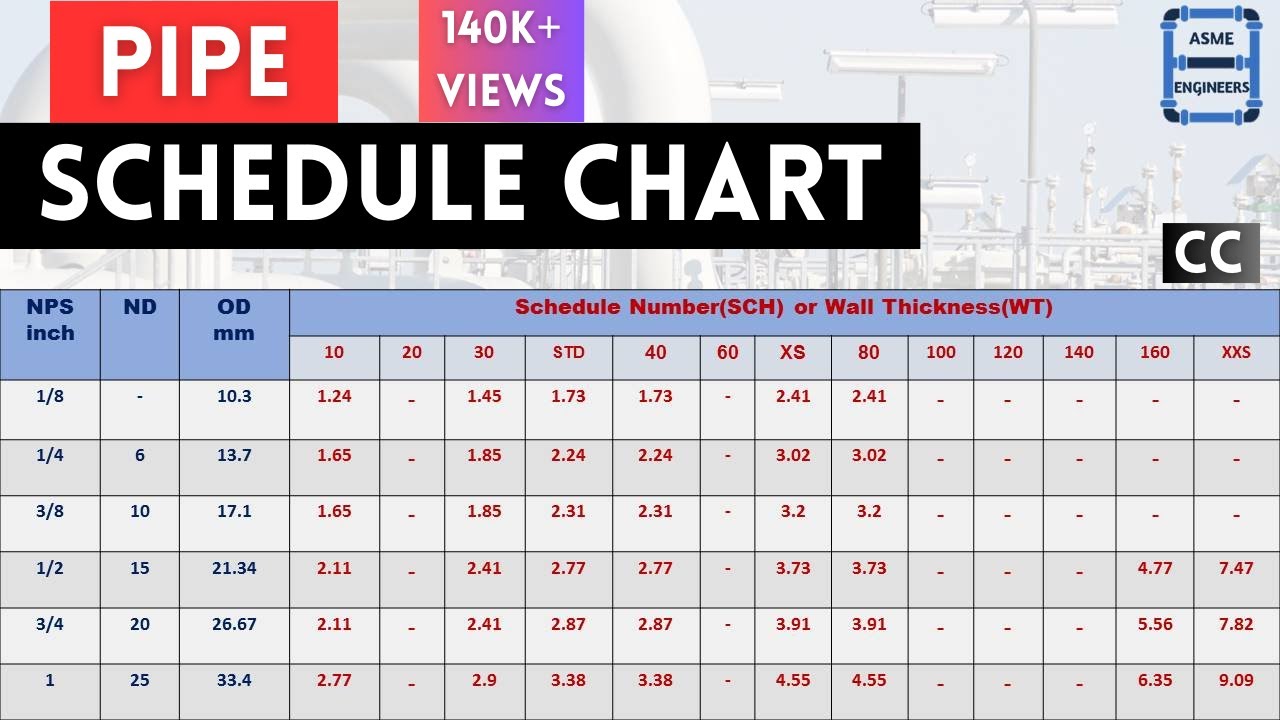

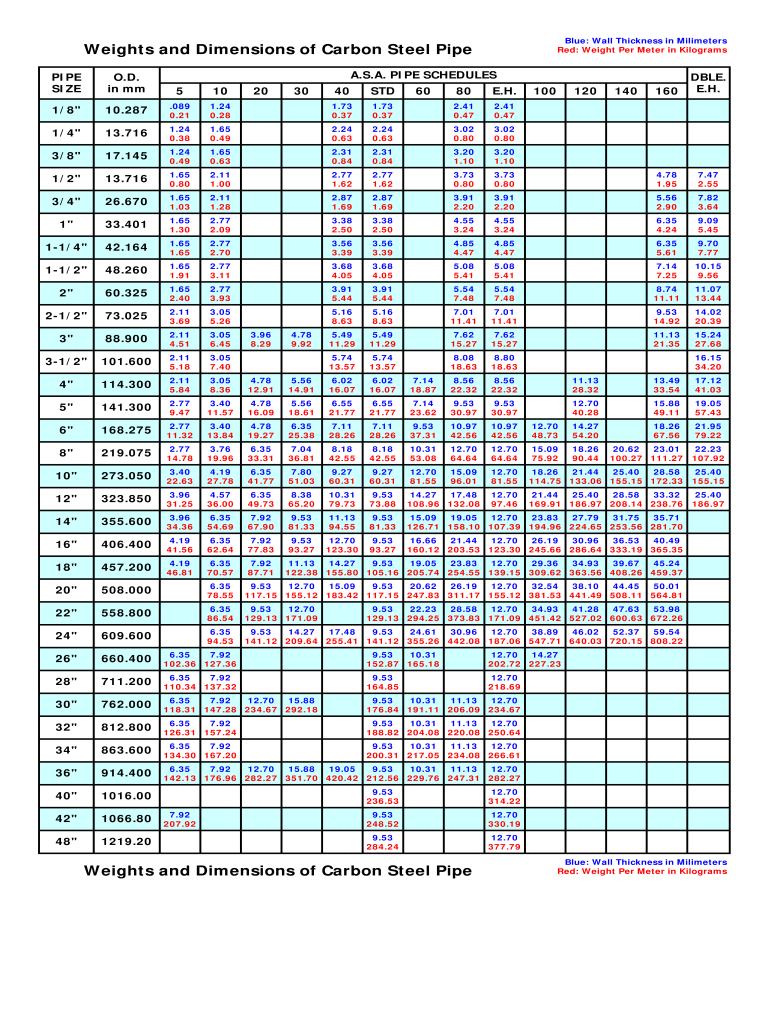

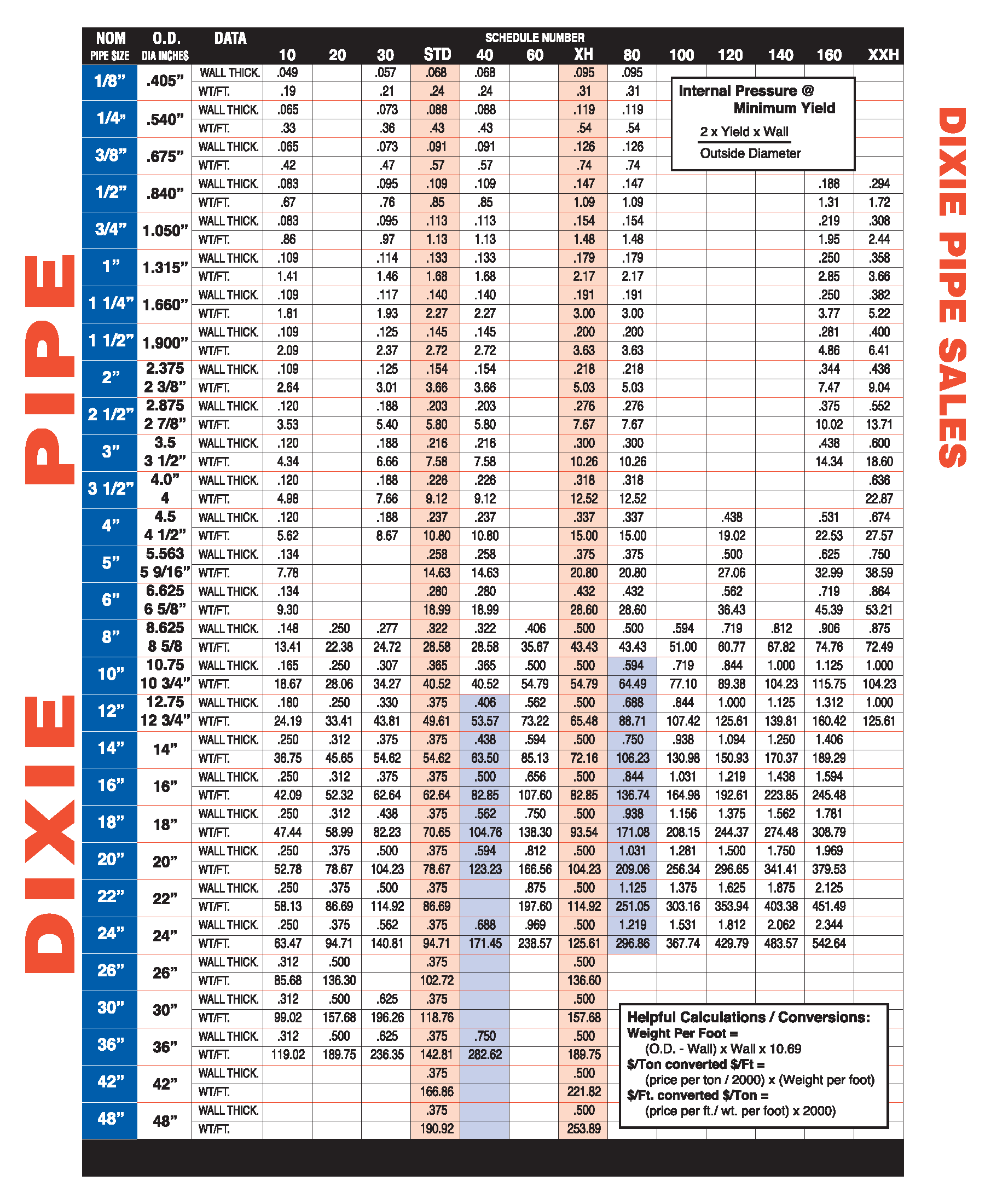

Product Catalog Pipe dimension chart (11×17) Click to Print Our Pipe Dimension Chart ANSI Pipe Chart Use our ANSI Pipe Chart to determine the nominal pipe size, wall thickness, weight and schedule designations. For easy reference, print out this up-to-date chart. Click to Print Our Line Sheet Pipe Chart Spreadsheet - Average Wall Thickness

Pipe Schedule Chart ASME B36.10 YouTube

Pipe Color Code Charts that cover all of the major pipe marking standards in the U.S. are available free. ANSI A13.1 Pipe Color Code Chart: ANSI A13.1 pipe marking code is the standard most often used for pipe marking. An estimated 90% of all pipes are marked using the ANSI standard. The ANSI A13.1 Pipe Color Code Chart shows the required text.

ASTM Pipe Material Code CS, SS, LTCS, जाने मटेरियल कोड के बारे में। YouTube

These codes designate common material standards. ASTM A 53 Gr. B - Carbon Steel Seamless and Welded Pipe. ASTM A106 Gr. B - Carbon Steel Seamless Pipe. ASTM A 672 Gr. B60 - Carbon Steel ERW Welded Pipe. ASTM A333 Gr. 6 - Low-Temperature Carbon Steel Seamless and Welded Pipe.

Pipe Color Code

Pipe types: The chart may also include information on the different types of pipes used in a piping system, such as metal, plastic, or composite pipes, and how they should be identified. Pipe color coding charts are often based on industry standards, such as ANSI/ASME A13.1 in the United States or BS 1710 in the United Kingdom.

Pipe OD ID and schedule chart dimensions in mm PDF

ANSI/ASME A13.1 is the pipe identification standard most commonly used in the United States. The standard specifies the primary and secondary means of identifying pipe contents, as well as the size, color and placement of the identification device. PRIMARY PIPE IDENTIFICATION

ISO14726 (Color Marking on Pipes) [PDF Document]

Using Pipe Color Code Charts Creating Custom Labels for.

Pipe Color Code Standard and Piping Color Codes Chart

The ASME A13.1-2023 American National Standard outlines legends for identifying the components of a piping system (including content descriptions like "HOT WATER" OR "PROPANE"), color, placements, the type and size of letters, provisions for abandoned piping, and GHS (Globally Harmonized System of Classification and Labelling of Chemicals) picto.

Pipe Schedule Metric Fill and Sign Printable Template Online US Legal Forms

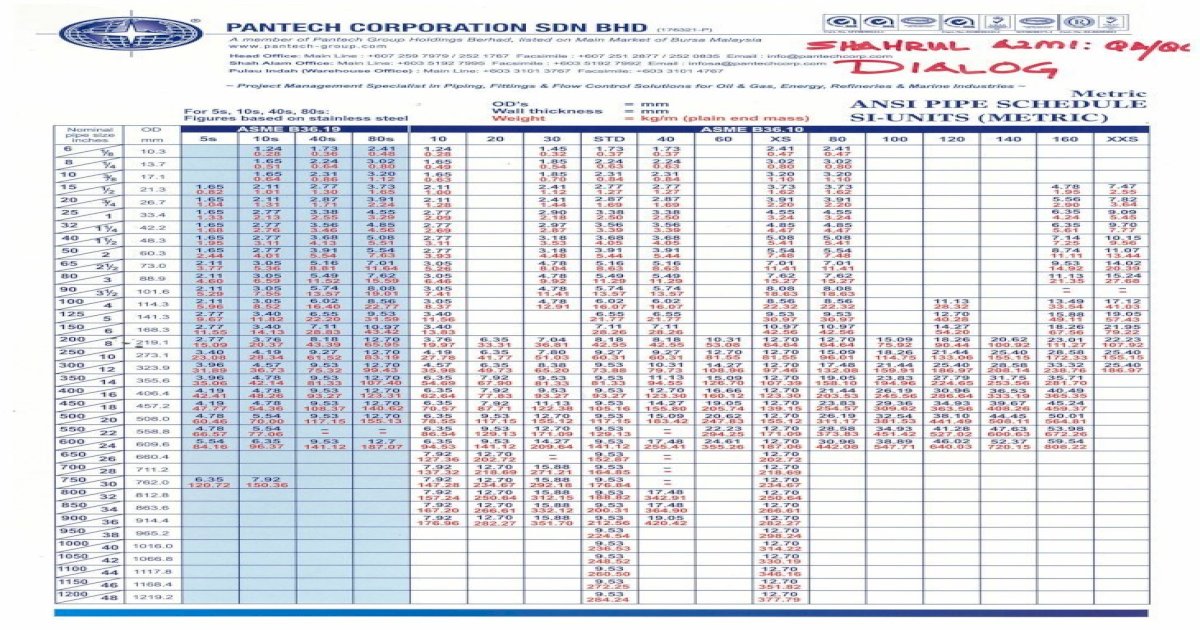

The following chart gives standard pipe schedule or pipes sizes as given by ANSI / ASME B36.10M and API 5L . Data given in based on the NPS Tables given by ANSI B36.10M and includes Pipe wall thickness, outside diameter, nominal diameter. ANSI - American National Standards Institute ASME - American Society of Mechanical Engineers

PIPE METAL CODE CHART / AND PIPE COLOR CODE CHART FOR PIPE FITTER WELDER AND PIPING ENGINEER

BS 1710 - Specification for Identification of Pipelines and Services. IS 2379 - Pipelines Identification Color Code. PFI ES-22 - Recommended Practice for Color Coding of Piping Materials. ANSI/ASME A13.1 Pipe Color Code Standards Explained :-. Industry's and factories in which piping system is available should familiarize themselves with.

ANSI Pipe Schedule

Process Piping Fundamentals, Codes and Standards - Module 1 A.Bhatia 5 • Schedule 80 steel pipes will be heavier and stronger than schedule 40 pipe. • Schedule 80 pipe will provide greater factor of safety allowing it to handle much higher design pressures. • Schedule 80 pipe will use more material and therefore costlier to make and

Inspection Clour Code 5s Color Chart Bambu Darcie Hurst

By pipesfactory | 2019-03-17T16:04:56+00:00 March 14th, 2019 | Categories: Steel Pipes | Tags: pipe color code chart and standard, steel pipes | 0 Comments Share This Story, Choose Your Platform! Facebook Twitter Reddit LinkedIn Pinterest Vk

Piping Color Code Chart PDF Pipe (Fluid Conveyance) Building Engineering

ASTM A312 (TP 304, 316, 321, 347, etc): Standard specification for seamless, straight-seam welded, and cold worked welded austenitic stainless steel pipe intended for high-temperature and general corrosive service ASTM A790: Specification for seamless duplex and super duplex pipes (UNS S32205/31803 and UNS S32750/32760) CAST VALVE MATERIALS

A Guide to Pipe Marking Standards Creative Safety Supply

The reason pipe marking is a little less straightforward is because OSHA's standard on the issue, 29 CFR 1910.261 (a) (3) (ii), only states: Scheme for the Identification of Piping Systems, A13.1 - 1956. OSHA references the standard from ANSI, the American National Standards Institute, but it doesn't refer to the most current version.

Pipe Chart Dixie Pipe

IS 2379 - Pipelines Identification Colour Code These standard uses different color code methodology to identify the pipe material. They use a base color, band color, letters, and direction arrow to identify fluid inside the pipeline. ANSI/ASME A13.1 - Scheme for the Identification of Piping Systems